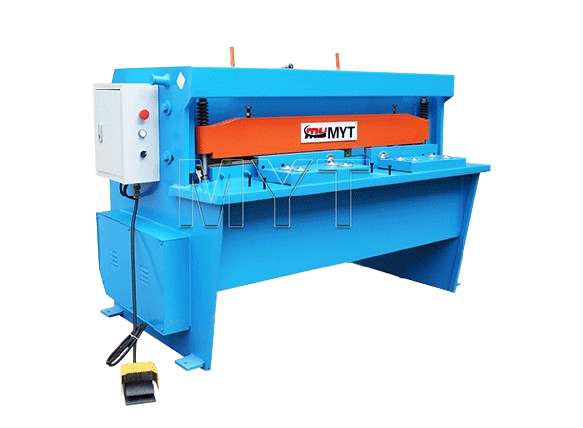

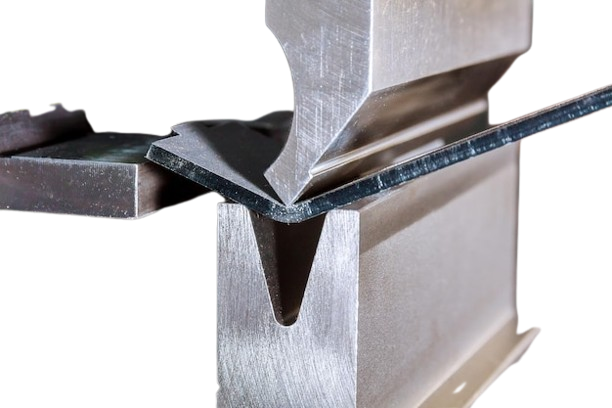

MR Engineering Services is a popular modern industry for the past 5 years. we have been pioneers in the field of sheet metal fabrication. We do sheet metal shearing, folding using CNC bending machines up to 12mm thickness. Along with this we have excelled in Laser cutting for the past 5 years and we are proud to say that we are the best in the field of laser cutting as our maximum capacity to cut is 25mm for Mild Steel material and 16mm for all other non ferrous materials like Stainless Steel, Aluminum. As inclusion to Laser cutting we have made new advancements in the same field by introducing Laser Scanning Cutting by which we can cut Copper & Brass. We make various laser cutting components as per industries requirements. We always focus on quality part. Laser provides excellent cut quality and productivity on material less than 6 mm and provides unparalleled levels of precision.

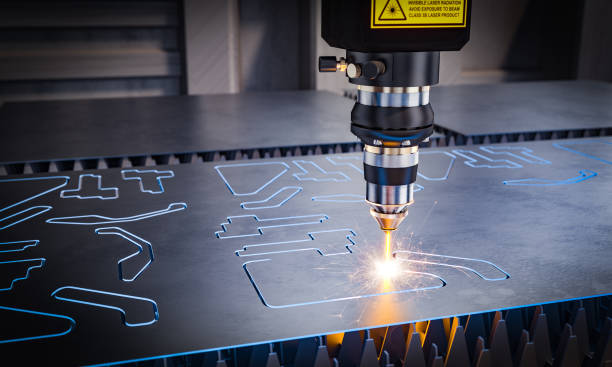

CNC Laser Cutting

MR Engineering Services CNC laser cutting is a sheet metal manufacturing process carried out by CNC laser cutters. The primary form of laser cutting for sheet metal is ‘vaporization cutting’, in which the laser beam melts the material and a high pressure gas removes the molten material. We bring forth vast industrial experience and expertise in this business, involved in offering a high-quality range of Pre Engineered Building Shed. Our products are high in demand due to their premium quality and affordable prices. Furthermore, we ensure to timely deliver these products to our clients, through this we have gained a huge clients base in the market. Features: Precision Cutting Versatile Speed Non-Contact Process.